In today's fiercely aggressive production landscape, firms experience a twin challenge: the relentless stress to boost effectiveness and decrease operational charges, coupled with a increasing crucial to adopt sustainable tactics. Energy prices fluctuate, skilled labor is usually scarce and expensive, and customers and regulators alike demand from customers greener operations. For industries depending on bottling and filling processes – from food and beverage to cosmetics and prescription drugs – these pressures converge right over the creation line. standard filling devices, typically rigid in style and demanding sizeable manual intervention, could become bottlenecks, consuming abnormal Vitality for the duration of operation and changeovers, creating squander, and inflating labor prerequisites. having said that, a fresh technology of liquid bottle filling equipment provide is rising, created to the principles of adaptability and automation. These Highly developed systems provide a strong Remedy, right addressing the Main difficulties by enabling multi-item adaptability and intelligent operation, paving the way for leaner, greener, and much more rewarding manufacturing. This exploration delves into how these crucial features translate into tangible Gains, reworking output floors and setting new benchmarks for operational excellence.

Table of contents:

Taming the Changeover Beast: the strength of Multi-Specification Compatibility

Multiplying Throughput: The effectiveness Gains of Multi-Head Filling

Empowering Your Workforce: The Simplicity of click here sensible Human-Machine Interfaces (HMI)

creating the Lean and inexperienced Line: Automation from start off to Finish

long term-Proofing Your Investment: Adaptability and prolonged tools Lifecycles

Taming the Changeover Beast: The Power of Multi-Specification Compatibility

among the list of most significant drains on effectiveness and means in classic filling lines will be the changeover approach. Switching creation between distinct product measurements, shapes, or formulations generally requires considerable downtime. This isn't just dropped production time; it is a duration of appreciable squander. Mechanics might need to physically swap out a number of structure parts or full machine sections, a approach that could take several hours. for the duration of this time, Strength is eaten by auxiliary devices although the most crucial line isn't really jogging. Trial runs just after set up normally result in product wastage – product or service, containers, and packaging – right up until the road is beautifully dialed in. Moreover, the necessity to support various product portfolios usually forces makers to speculate in various dedicated filling lines, Just about every consuming space, cash, and ongoing Electrical power, regardless if idle.

modern-day filling equipment engineered for versatility fundamentally transform this equation. Imagine a single device effective at handling an exceptionally wide range of container requirements – As an illustration, accommodating bottle diameters from as little as 20mm around 160mm, and heights spanning from 30mm to 350mm. This wide compatibility removes the need for intensive mechanical reconfiguration between numerous merchandise operates. changes will often be application-pushed or call for only minor, fast-change tooling.

The benefits are instant and substantial. First of all, downtime is dramatically decreased. Changeovers that Earlier took several hours may well now be accomplished in minutes. This specifically translates to amplified output capacity and more quickly reaction situations to marketplace calls for. Secondly, Electrical power usage plummets. Shorter changeover periods mean a lot less idle Strength use. More critically, the chance to operate a number of goods on a single, flexible line avoids the significant cumulative Strength draw linked to working and maintaining several devoted, significantly less-used strains. Thirdly, material waste during setup and demo runs is minimized. speedier, much more precise changes lessen the number of scrapped containers and wasted product or service. This inherent performance does not just save money; it aligns beautifully with sustainability plans by lessening the environmental footprint associated with source use and waste era. This flexibility is actually a cornerstone of lean production applied to the filling course of action.

Multiplying Throughput: The effectiveness Gains of Multi-Head Filling

manufacturing velocity is actually a significant metric for virtually any company. escalating output per hour straight impacts profitability and a chance to fulfill shopper orders immediately. whilst line pace is very important, the filling station by itself is commonly the rate-limiting move. common one-head fillers, while dependable, can only method 1 container at any given time.

Innovative filling systems overcome this limitation by way of multi-head configurations. By incorporating several filling nozzles functioning in parallel, these machines can course of action numerous containers concurrently in the very same machine cycle. This method can yield a immediate multiplication of throughput – a 4-head filler can most likely quadruple the output of only one-head machine, an eight-head filler can enhance it eightfold, and so forth, assuming downstream processes can hold tempo.

The impact on Power performance is profound. Achieving a goal production quantity will take considerably fewer operational time. If a multi-head machine can fill the every day quota in half time in comparison with only one-head unit, its overall energy use for that production operate is greatly minimized, although its instantaneous electrical power draw is a little bit better. This interprets to lessen Strength fees for each unit made, a key general performance indicator for sustainable operations. On top of that, this superior-throughput functionality is particularly advantageous for makers handling big batches of various products. It allows for fast completion of varied orders, minimizing the cumulative operational hrs and linked energy use across the entire solution blend, when compared with slower, sequential processing on considerably less successful products.

Empowering Your Workforce: The Simplicity of clever Human-device Interfaces (HMI)

sophisticated equipment generally calls for really proficient operators for setup, operation, and troubleshooting. Recruiting, schooling, and retaining these specialized personnel may be a substantial obstacle and price. Errors during handbook setup may lead to highly-priced faults, which include incorrect fill volumes, merchandise spillage, or maybe devices destruction. The reliance on specialized know-how may also create operational vulnerabilities if important personnel are unavailable.

The combination of refined however user-helpful Human-Machine Interfaces (HMIs) combined with Programmable Logic Controllers (PLCs) addresses these difficulties head-on. modern-day filling machines significantly feature intuitive touchscreen interfaces that existing operational parameters, diagnostic info, and control functions in a clear, graphical structure. These devices are suitable for simplicity of use, making it possible for operators with common instruction levels to deal with the machine effectively.

Recipe administration can be a critical aspect enabled by PLC Command. when the exceptional parameters for a selected item and container combination are identified (fill quantity, pace, nozzle timing, and so forth.), they can be saved being a recipe. When that solution needs to operate once again, the operator just selects the saved recipe, as well as machine mechanically configures alone. This considerably lessens setup time, minimizes the prospect of human mistake for the duration of manual parameter entry, and makes sure consistent high-quality run right after operate. This simplicity of use not just lowers the talent threshold needed for Procedure, decreasing dependence on highly specialized labor, but also boosts General operational effectiveness by minimizing set up faults and dashing up transitions in between items. It democratizes equipment Procedure, generating Sophisticated know-how available and responsible for the broader range of producing personnel.

developing the Lean and inexperienced Line: Automation from get started to complete

though the filling equipment is central, correct operational performance emanates from integrating it seamlessly into a bigger automatic workflow. Manual processes like loading bottles on to the line, transferring them in between stations, capping, labeling, and packing are labor-intense, vulnerable to inconsistency, and may introduce bottlenecks that negate the velocity benefits of a complicated filler.

fashionable versatile filling equipment are created with integration in your mind. they will commonly link with upstream and downstream automation devices, like automatic bottle unscramblers, conveyor systems, capping machines, labelers, and circumstance packers. This makes a cohesive, automatic creation line the place containers move easily from get started to finish with minimum human intervention.

the advantages increase significantly outside of labor Value reduction, While That may be a Principal driver, specifically in regions with superior labor fees. Automation assures consistency. devices carry out responsibilities frequently with significant precision, reducing variability in merchandise high quality and reducing squander caused by managing faults. In addition it enhances worker basic safety by taking away staff from potentially repetitive or harmful tasks. From a sustainability perspective, a completely automatic line optimizes workflow, minimizes cease-start out inefficiencies, and ensures that means – elements, Electrical power, and human capital – are employed as correctly as is possible. This holistic approach to automation, typically facilitated by a educated liquid bottle filling machine provider effective at planning integrated alternatives, creates A very "a lot less-manned" or possibly even "lights-out" operation, symbolizing the top of lean and eco-friendly production ideas.

potential-Proofing Your financial commitment: Adaptability and Extended tools Lifecycles

Markets evolve, consumer preferences alter, and products innovation is continuous. makers regularly introduce new items, variations, or packaging formats. With standard, inflexible machinery, adapting to those alterations could be tricky, high-priced, or impossible, frequently bringing about premature equipment obsolescence. Replacing equipment ahead of the stop of its probable beneficial daily life is don't just a major cash expenditure but also carries a substantial environmental burden linked to manufacturing new gear and disposing in the previous.

The inherent adaptability of contemporary filling machines presents a strong kind of future-proofing. due to the fact these units are intended to deal with a wide range of product or service types (liquids, creams, pastes) and container formats via parameter adjustments as opposed to key structural improvements, they can certainly accommodate new products as They can be designed. A equipment acquired right now remains related and effective at the same time as the corporate's product portfolio expands or shifts. This concept of "a person device, numerous takes advantage of" maximizes the return on investment.

a lot more importantly, this adaptability considerably extends the gear's operational lifecycle. By delaying or keeping away from the necessity for substitute, brands lessen the desire for new useful resource-intensive equipment production. Furthermore, it minimizes the squander stream affiliated with scrapping out-of-date tools. deciding upon equipment suitable for extensive-term flexibility is as a result a fundamentally sustainable choice, reducing the general environmental effects related to capital items after some time. A reliable paste filling equipment manufacturer concentrating on such adaptable styles inherently contributes to a far more circular financial system throughout the manufacturing sector.

The trail in direction of a far more profitable and sustainable manufacturing upcoming is paved with clever investments in technological innovation that addresses Main operational problems. while in the realm of product filling, the convergence of multi-products adaptability and complex automation offers a compelling Resolution. By reducing changeover waste, maximizing throughput with multi-head patterns, simplifying operation via intuitive interfaces, enabling seamless line integration, and foreseeable future-proofing investments with inherent adaptability, these advanced filling programs specifically combat soaring Power expenditures and labor pressures. They empower brands to become leaner, extra agile, and appreciably greener. The ability to minimize Vitality use for each device, limit substance waste, and extend machines lifecycles are no longer just appealing attributes; They can be critical elements of liable and aggressive modern-day manufacturing. corporations seeking these advanced abilities typically change to skilled suppliers known for sturdy and flexible solutions, including the systems created by Jiaren, to obtain their operational and sustainability aims.

Hallie Eisenberg Then & Now!

Hallie Eisenberg Then & Now! Richard "Little Hercules" Sandrak Then & Now!

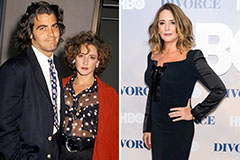

Richard "Little Hercules" Sandrak Then & Now! Talia Balsam Then & Now!

Talia Balsam Then & Now! Kane Then & Now!

Kane Then & Now! Pauley Perrette Then & Now!

Pauley Perrette Then & Now!